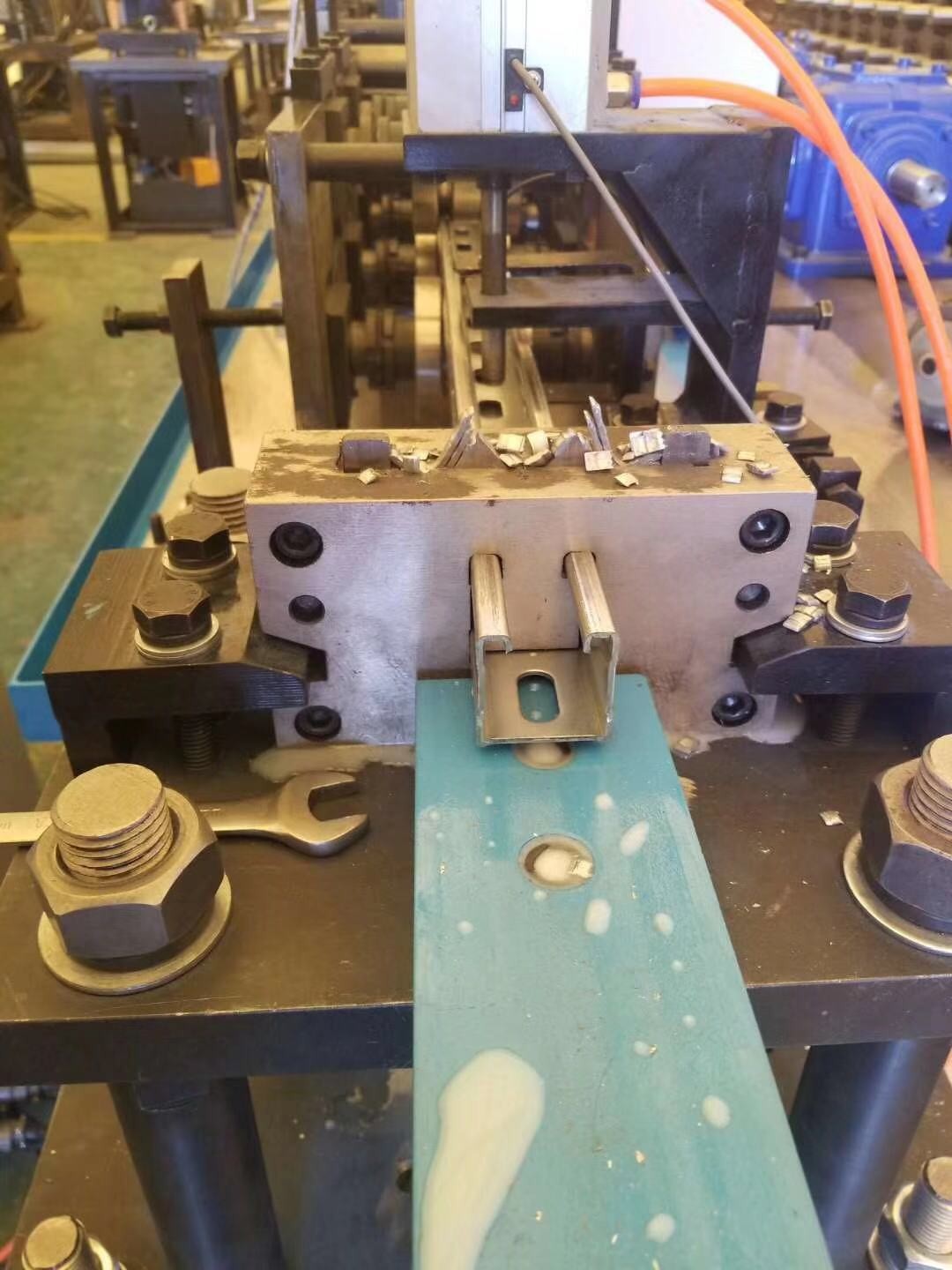

Fully automatic seismic bracket forming machine

- China

- 1000 units / year

The anti-seismic bracket is processed by cold bending of hot coil plate. With thin wall, light weight, excellent cross-section performance and high strength, it can save 30% of the material under the same strength,compared with traditional channel steel. It belongs to high efficiency and economic cutting profile. Because of the reasonable cross-section shape, they can make the steel more effective and improve the steel cutting ability.It is widely used in purlin and wall beam of steel structure building, and can be combined into light weight roof frame and bracket.In addition, it can also be used for column, beam and arm in light industry manufacturing etc.

Composition of anti-seismic support shaping machine : manual material frame, leveling, servo feeding, punching, shaping, hydraulic cutting, feeding table, PLC control cabinet

Work flow of anti-seismic support: uncoiling-feeding-punching-cold bending forming-length acquisition-cutting-unloading-completion

It can be fully automatic control and automatic cut-off after forming to set length with good straightness and high smoothness.As cut-off part with cylinder cushion structure and electronic monitoring,it can automatically stop when finding fault. It is safe and reliable.

The anti-seismic bracket is processed by cold bending of hot coil plate. With thin wall, light weight, excellent cross-section performance and high strength, it can save 30% of the material under the same strength,compared with traditional channel steel. It belongs to high efficiency and economic cutting profile. Because of the reasonable cross-section shape, they can make the steel more effective and improve the steel cutting ability.It is widely used in purlin and wall beam of steel structure building, and can be combined into light weight roof frame and bracket.In addition, it can also be used for column, beam and arm in light industry manufacturing etc.

Composition of anti-seismic support shaping machine : manual material frame, leveling, servo feeding, punching, shaping, hydraulic cutting, feeding table, PLC control cabinet

Work flow of anti-seismic support: uncoiling-feeding-punching-cold bending forming-length acquisition-cutting-unloading-completion

It can be fully automatic control and automatic cut-off after forming to set length with good straightness and high smoothness.As cut-off part with cylinder cushion structure and electronic monitoring,it can automatically stop when finding fault. It is safe and reliable.